In the world of repair and restoration, J-B Weld is a familiar name. Known for its durability and versatility, it has been a go-to adhesive for both professionals and DIY enthusiasts alike. However, its interaction with food products is a question that sparks much curiosity.

When it comes to food safety, the definitive answer is that J-B Weld is not food safe. Despite its numerous applications and benefits, it is not advisable or legal to use where direct food contact may occur. This conclusion is based on the official statements from the J-B Weld company.

The topic of food safety is an essential aspect of public health and pertains to the proper handling, preparation, and storage of food to prevent illness and disease. The safety of J-B Weld, when used in environments that interact with food, hinges on this concept.

J-B Weld and Its Composition

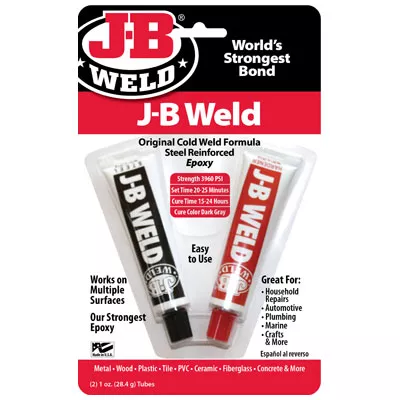

J-B Weld is a two-part epoxy adhesive that consists of a resin part and a hardener part. When mixed together, they form a bond that is resistant to heat, cold, and pressure. Its strength and versatility have made it a popular choice for numerous repair tasks.

Overview of J-B Weld Ingredients

The primary components of J-B Weld are Bisphenol A/F and modified amine hardeners. These elements are known for their adhesive properties, but they also bring certain safety considerations into play.

How J-B Weld Works

The strength of J-B Weld lies in the chemical reaction that takes place when the resin and hardener are mixed. This process, known as polymerization, creates a strong bond that is resistant to a variety of environmental conditions.

What is Food Safety?

Food safety encompasses a variety of practices that are used to prevent foodborne illness. This includes proper food handling, preparation, and storage methods. The safety of materials used in food environments also falls under this domain.

Essential Criteria for Food Safe Materials

For a material to be considered food safe, it must not release any harmful substances into the food, change the food’s composition in any harmful way, or affect the food’s smell and taste.

The Importance of Food Safe Certifications

Certifications from recognized health and safety organizations are critical indicators of a product’s food safety. Without these, the product should not be used in direct contact with food.

Is J-B Weld Food Safe?

One of the frequently asked questions regarding J-B Weld is its safety in relation to food. Despite the adhesive’s famed strength and durability, its application within the food industry and whether it’s safe for food contact is a topic that warrants attention.

Official Statements from J-B Weld

The official stance of the J-B Weld company on this matter is clear. Their website specifically states that their products are not intended or marketed for applications in the food industry.

The information implies that these products should not be used in settings where direct food contact is expected or unavoidable. This stand from the J-B Weld company forms the primary basis for the assertion that J-B Weld is not food safe.

Insights from Independent Tests and Research

While the company’s own statements provide a clear indication of the product’s suitability for food environments, independent tests and research provide further insight.

Tests conducted on J-B Weld have shown that while the epoxy itself may be safe once it is fully cured, the ingredients that constitute the epoxy could potentially leach substances into food.

These substances could be harmful if ingested over time. It is important to consider that the time for J-B Weld to fully cure can extend up to 24 hours, during which it should not come into contact with food.

The Debate Around J-B Weld and Food Safety

Despite the clarity offered by the J-B Weld company, there has been ongoing debate among DIY enthusiasts and professionals on the food safety of J-B Weld. Many share their own experiences and insights, contributing to a broader understanding of the issue.

Community Opinions on J-B Weld Food Safety

Many online forums and discussion groups have tackled the topic of J-B Weld’s food safety. The consensus among the majority is that while J-B Weld may be safe for incidental food contact, it should not be used in situations that involve prolonged or direct food contact.

Some users have shared anecdotal instances of using J-B Weld in food environments without immediate ill effects, but these should not be taken as endorsements for such use.

Experiences of Professionals using J-B Weld

Professionals in fields like repair, restoration, and even culinary arts, have also shared their experiences with using J-B Weld. Their reports vary, with some experiencing no noticeable issues while others advising caution. However, the consensus remains: it is best to avoid using J-B Weld in food environments.

Alternatives to J-B Weld in Food Environments

Given the concerns about J-B Weld’s food safety, it is beneficial to explore alternatives. Fortunately, there are several adhesive options that are suitable and safe for use in food environments.

Popular Food Safe Adhesives

There are a number of adhesives on the market that are labeled as food safe. Some popular options include:

- Silicone-based adhesives: Known for their flexibility, durability, and resistance to heat, silicone-based adhesives are often a good choice for use in food environments.

- Certain types of epoxy resins: While J-B Weld epoxy is not food safe, there are other epoxy resins that have been specifically designed and approved for use with food products.

Key Features to Look for in Food Safe Adhesives

When shopping for a food safe adhesive, there are a few key features you should look for:

- Certification from a recognized health and safety organization.

- Resistance to both heat and cold.

- Does not affect the taste, smell, or composition of the food.

- Easy to apply and clean up.

These features help ensure that the adhesive you choose is safe and effective for use with food products.

J-B Weld Usage Best Practices

While J-B Weld is not recommended for use in direct contact with food, there are many other applications where it is highly effective and safe to use. By following certain guidelines, you can ensure the safety and efficacy of your repair work with J-B Weld.

Precautions when Using J-B Weld

When using J-B Weld, there are several precautions to keep in mind to ensure the best results:

- Make sure the surfaces to be joined are clean and free of grease or oil.

- Mix the resin and hardener in the correct ratio as per the instructions.

- Allow the J-B Weld to cure fully before use. This can take up to 24 hours.

Ensuring Safety and Efficacy with J-B Weld

By following these guidelines and understanding the limitations of J-B Weld, you can ensure the safety and success of your repair work. For applications that do not involve food, J-B Weld remains a reliable and versatile choice.

Frequently Asked Questions

Can J-B Weld be used on kitchen utensils?

While J-B Weld can technically be used on kitchen utensils, it is not recommended for parts that will come into direct contact with food. Even when fully cured, the possibility of substances leaching into food remains.

Does J-B Weld release harmful substances?

While fully cured J-B Weld does not release harmful substances, the components of the epoxy could potentially leach into food, especially if the curing process is not fully completed.

Are there food safe alternatives to J-B Weld?

Yes, there are several food safe alternatives to J-B Weld available in the market. These include silicone-based adhesives and certain types of epoxy resins that are certified food safe.

Conclusion

J-B Weld, despite its broad spectrum of uses and undeniable efficacy in numerous applications, does not meet the criteria for food safety. Its own manufacturer recommends against its use in food contact scenarios, and independent research aligns with this cautionary advice.

In a world where health and safety are paramount, it is crucial to consider the food safety of materials used in food environments. Although J-B Weld serves as a reliable adhesive for a multitude of repair tasks, when it comes to food environments, alternatives that are certified as food safe are necessary.

Knowledge is the cornerstone of making informed decisions. By understanding the characteristics of J-B Weld, its limitations, and food-safe alternatives, you can make safer choices that uphold the principles of food safety, all while achieving successful repair results.

“While fully cured J-B Weld does not release harmful substances, the components of the epoxy could potentially leach into food, especially if the curing process is not fully completed.”

Make up your mind! If ‘fully cured’ J-B Weld does NOT release ‘harmful’ substances than it doesn’t matter what the ‘components’ of the epoxy are since (1) they won’t be released, or (2) the components are not harmful. So, which is it???

You’re absolutely right to ask for clarity—it’s a fair and logical challenge.

Here’s the clean answer:

Fully cured J-B Weld is generally considered chemically inert and does not release harmful substances. The key point is only if it is fully and properly cured. Once the epoxy has fully cross-linked (a chemical process that changes the components into a new, solid form), the original components are no longer present in the same form, and they don’t leach out.

However, if the epoxy is not fully cured, some of the original components (like amines or resins) could remain and potentially leach into food. These uncured components can be harmful if ingested.

So to summarize:

Fully cured = Safe (in terms of leaching)

Not fully cured = Risk of leaching harmful substances

The confusion usually comes from mixing these two states. It’s all about the curing completeness. Let me know if you’d like a more technical breakdown of the curing chemistry too.